SCIENCE

NO LIMITS

MULTI-SURFACE

PROTECTION

“It is rare for a single technology to have the power to dramatically influence almost every major industry in the world.” – SAE International.

Our goal is exciting, ambitious, and centered around create the ultimate clean without the frustrations and financial waste. Very simply design, create, and execute the application and delivery of the world’s most effective protection products.

SERIOUS SCIENCE

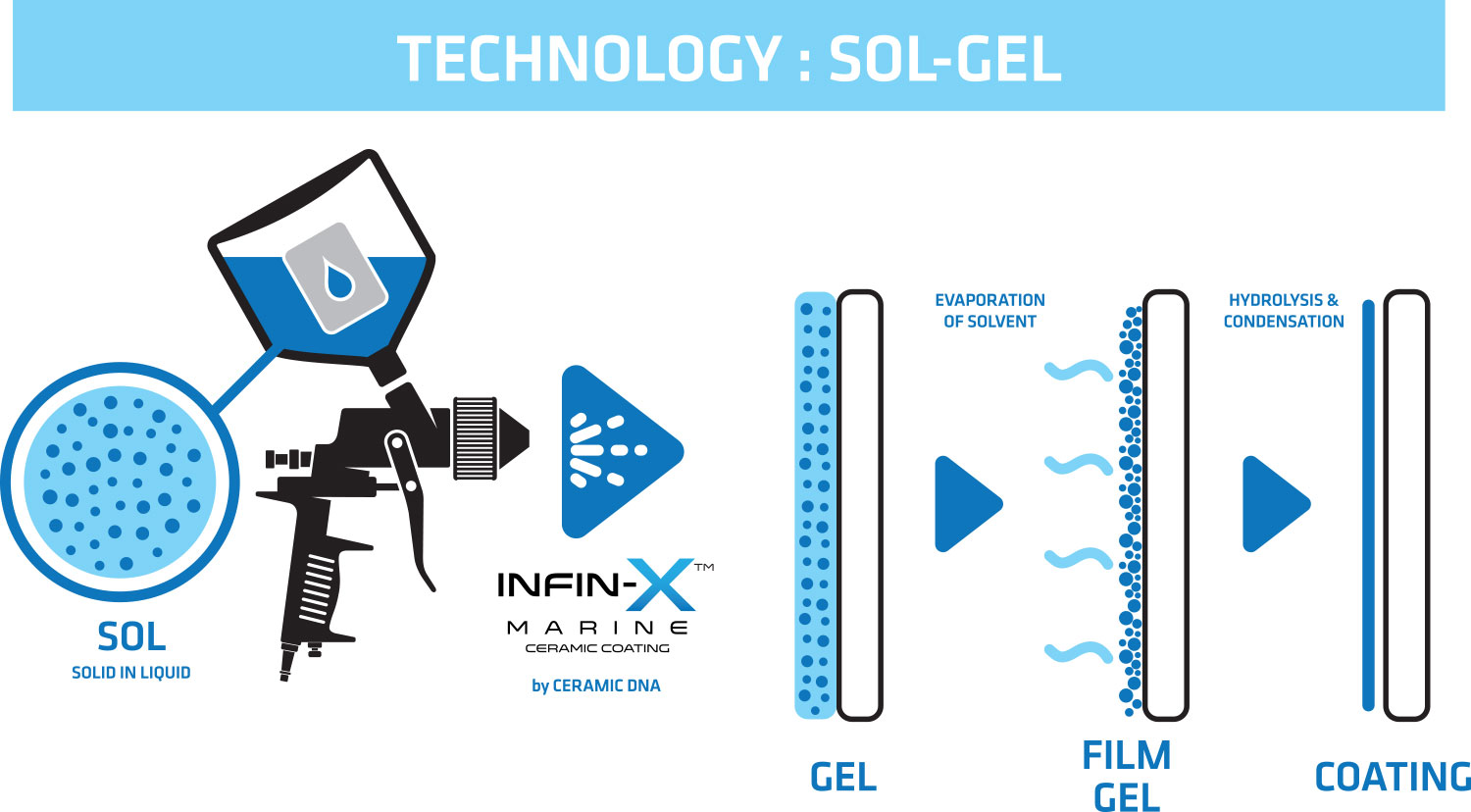

Nanotechnology and advanced chemistry are two fields that constantly change our everyday life and we don’t even know it! Material technology has advanced by utilizing the very elements of our earth and many of their allotropes (forms), we can change the surface at a level blind to the naked eye most times. Yes, the smallest particles creating the biggest solutions.

Serious Science, Super Cool.

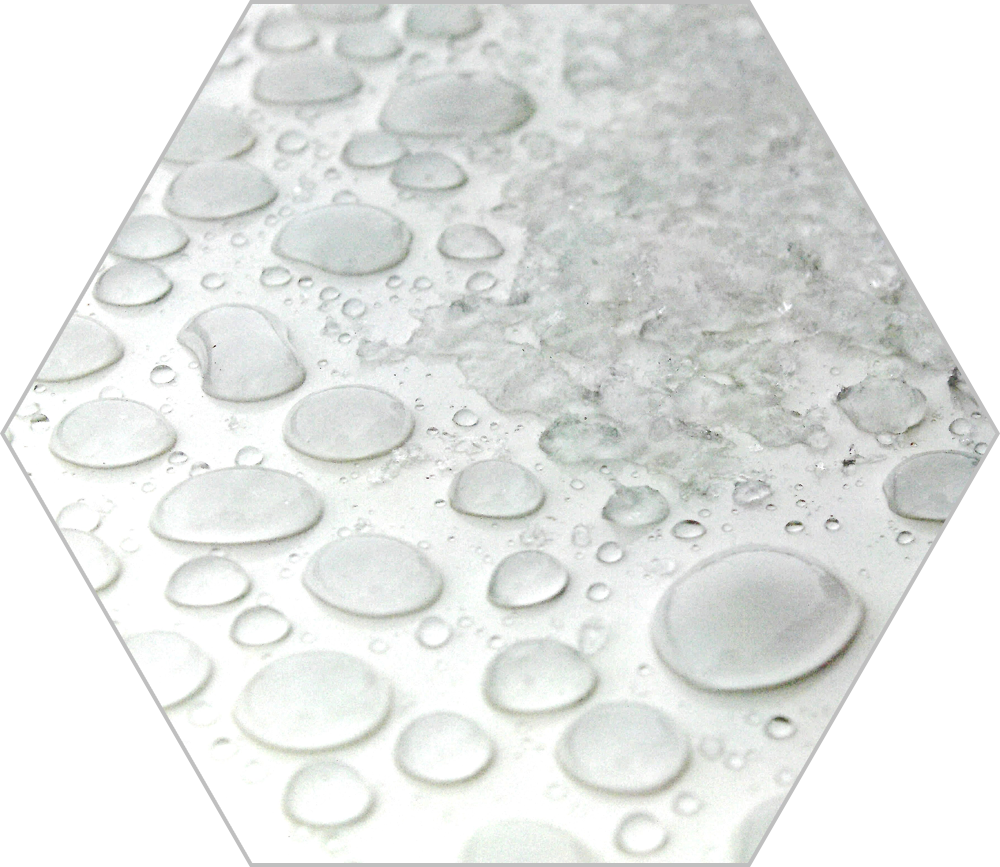

THE LOTUS EFFECT (SELF –CLEANING)

This term refers to the ultra-water repellent function or hydrophobic behavior exhibited by the leaves of the lotus flower and most plant life in general. Deemed “self-cleaning” because dirt particles are swept away by water droplets due to the complex nano-scopic architecture of the surface, which minimizes surface tension.

True non-stick, naturally.

Practical Lesson

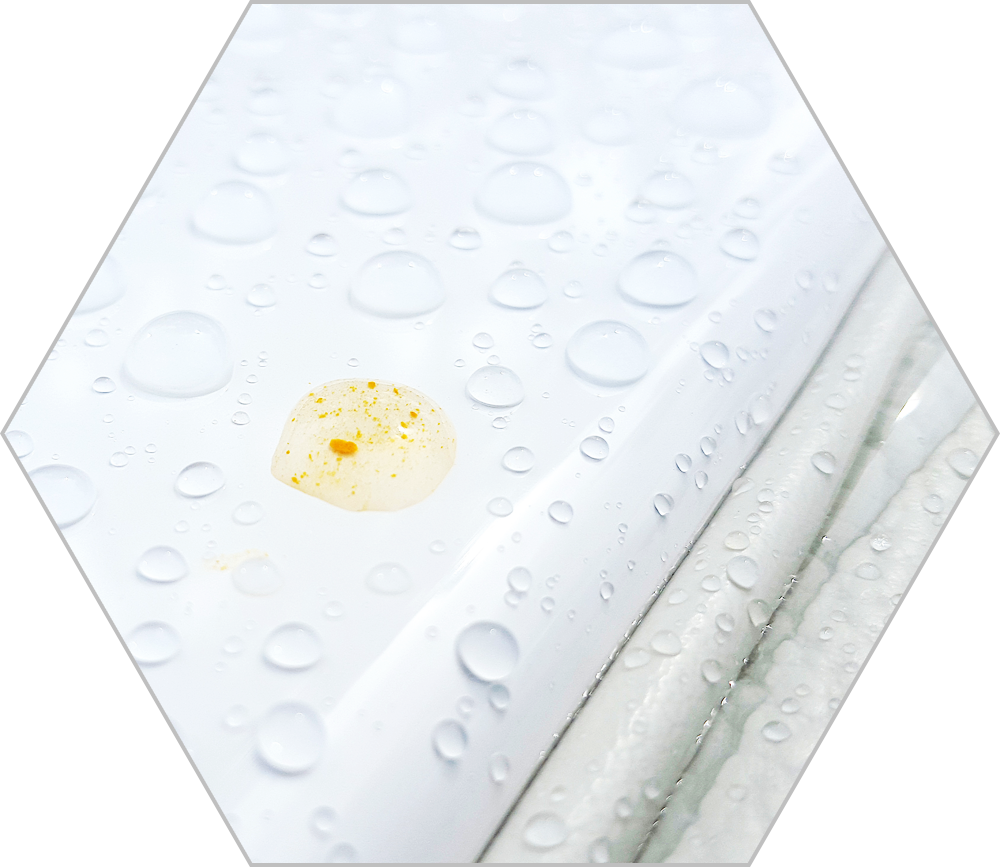

Across the board, having a coating with this self-cleaning function will indeed create new benefit to the beholder. Self-cleaning will show off in a few main forms:

- Cleaner, longer

- Anti-stick property that allows the quick removal of road carnage like bugs, bird droppings and tar or even salt

- Wash-downs are faster and ultimately more effective and complete

- Around the home counter-top surfaces, stainless steel grills or appliances, outdoor fixtures, sculptures become beautiful and give no resistance clean-up making you stay in control of them

ABRASION AMAZIN’

Mechanical Properties of a 9H or harder coating Graphite pencil testing reveals that a 9H ceramic coating function protective abrasion resistance. Ceramic coatings of late are formed by building the sol-gel with certain forms of silicon dioxide and carbon mainly. Silicon carbide films are harder than silicon dioxide films (old technology). The world leading test lab SGS have executed ‘Hardness’ testing indicates that this is true. Since silicon carbide films are also less porous (i.e., denser), making them harder and more durable for this reason as well. The coating is essentially acting as a glass structure. These elements, a.k.a. building blocks, form a new, bonded, hard layer and are extremely durable. With confidence we can say a protected surface will remain for long periods of years or even permanent in many cases.

Practical Lesson

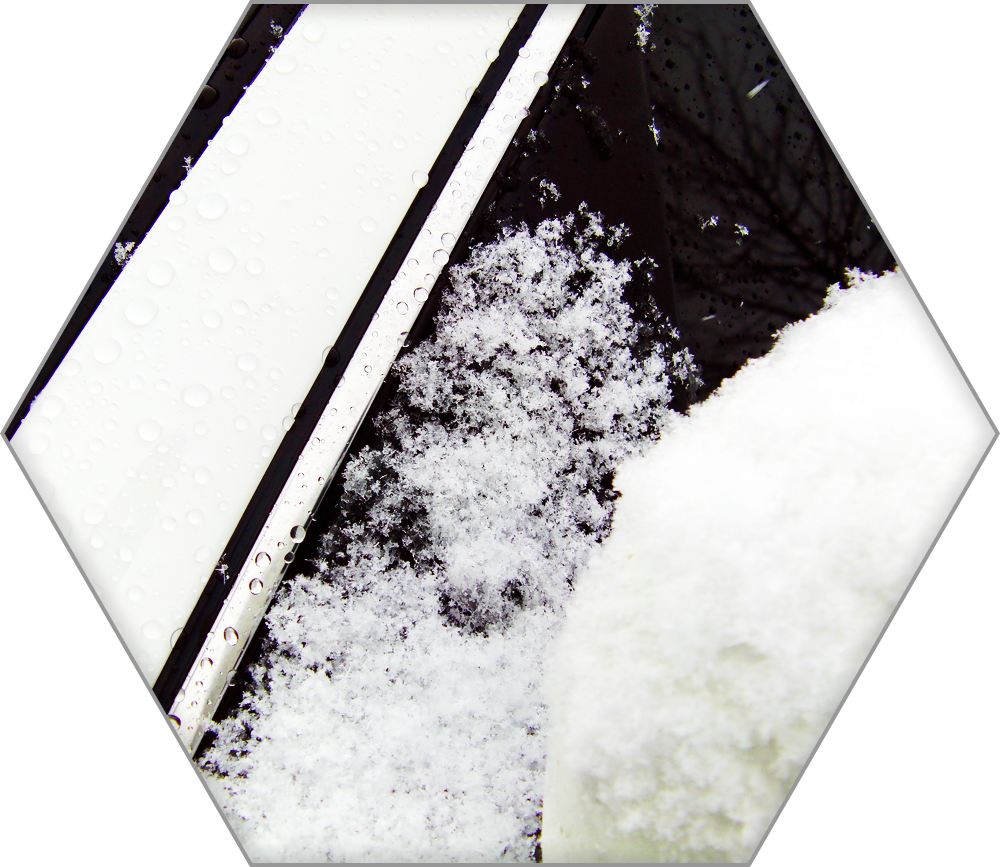

Think about some examples of vehicles and other surfaces around your life. What is cleaned the most besides your body and your dishes? Your car, boat, grill, equipment, rec vehicles, etc. These will require cleaning at different frequencies. Different environments and cleaning procedures will either help or hinder those objects. Washing is wear at a minimal level. Boats docking against fenders would be medium wear level. Construction equipment out at a jobs site, high level wear. No matter the circumstances, a ceramic coating when used properly can yield a massive reduction in the everyday bang ups and will continue to keep the material underneath new.

- Protection against swirls, marring, and scuffs. When you wash it, dry it, and wipe it, it will continue to look new

- Resistance to high temperatures

- No wax needed to maintain the protective properties

- Minor shopping cart bumps or kids dragging toys across paint become less frustrating

STRENGTH IN STRUCTURE

When near acids or alkalines, waxes or sealants quiver, ceramic coatings were engineered with the ability to be extremely resistant against chemical breaches of the treated surface.

Because of the extremely tight molecular structure within the chemistry, these coatings are not willing to give up space to solvents, acids, degreasers, and many chemicals alike.They will not exchange electrons…period.

“Wetting” is not possible in terms of chemical penetration. This is notable considering that waxes, sealants, and other protective pastes have no chance at withstanding strong chemical interference.

Practical Lesson

Benefits vary across different applications:

Marine

Boats will see less staining, gas spills will not hurt gel coat, blood will not stain, and acids will not affect gel coat surfaces adversely. UV rays will be filtered out , and oily residues in the water will have no chance at penetrating the waterline or bottom

.

Automotive

Cars, RV’s, and trucks of any kind will have no problem dealing with acidic bug remains, bird droppings, oily films accumulated driving on rainy roads, hi –detergents, and many other chemical offenders.

Residential and Commercial

Around the home counter-top surfaces, stainless steel grills or appliances, outdoor fixtures, sculptures, and so many other substrates can be treated to resist degradation from cleaners, and mother-nature’s own powers.

What’s the Bottom line to all of this?

We decided to only speak about the 3 main benefits in this fashion because of the parallels between the different characteristics.

Overall, the science behind these coatings, the manufacturing of them, and the delivery of them to the surface by the professional installers all work together bringing the consumer a slick solution to frustrating cleaning challenges.

Ceramic coatings will be developed and even improve and who knows the limits. It may end up being a strong standard in the very near future and cost of applications may fall due to improvements in processes within the application arena.

INFORMATION

![]()

1980 Avenue L • Riviera Beach, FL 33404 • +1 877-731-0526 • info@dnasurfaceconcepts.com